Additive Manufacturing

In recent years, additive manufacturing processes have been established in many areas of application. Layer building processes have become the key to short development times and an economical manufacturing system for complex component geometries and small to medium batch sizes. Additive manufacturing (AM) processes serve an ever broader range of applications.

Originally only known to research institutions, additive manufacturing technologies are now increasingly applied in the aviation industry, toolmaking and the automotive industry in order to strengthen production.

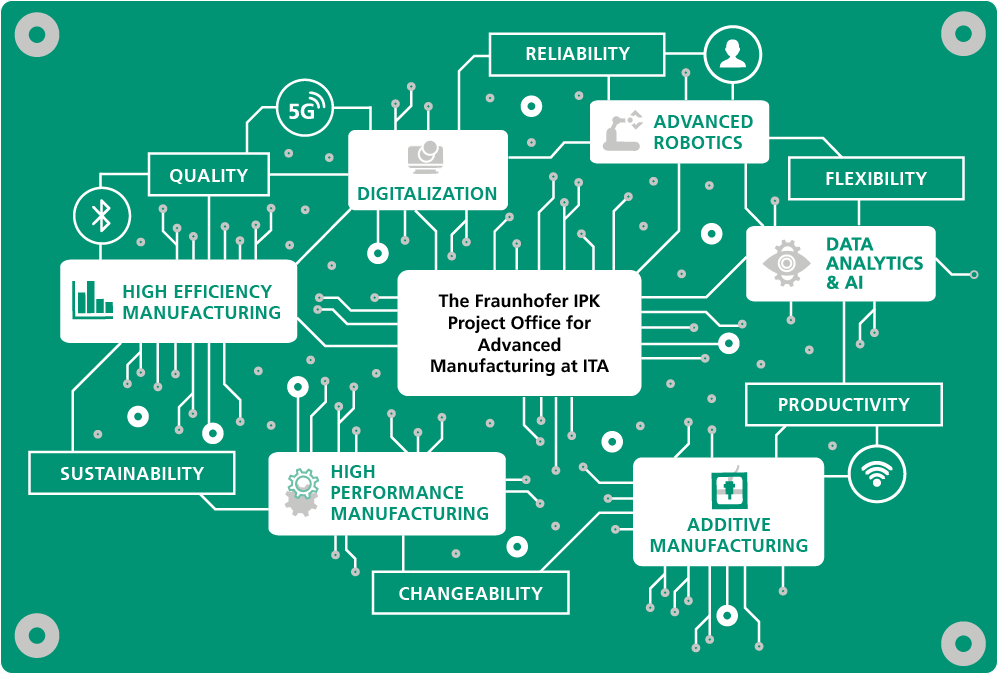

The Fraunhofer IPK Project Office for Advanced Manufacturing at ITA has expertise along the whole value chain of Additive Manufacturing. From optimized product design and simulation through process development up to post-processing and quality control, Fraunhofer IPK and ITA’s infrastructure and competences are ready to support industrial demands. Many metallic alloys and plastics can be safely processed and used for application fields from individual production to small series production. Customized components created on the basis of 3D CAD data can compete with conventionally produced goods in terms of material properties. In addition, tool-free production offers enormous advantages and added value in today’s production landscape.

Leer

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Material qualification for AM processes

📄 Qualification of CuCr1Zr for laser power bed fusion

Comeback of cooper in toolmarking

Economical and technical feasibility of AM applications

📄 Metal additive manufacturing

Laser powder bed fusion and directed energy deposition

📄 Expert Survey – AM Trends 2020

Future services and products of additive technologies

📄 Fast prototype

Additive manufacturing as a tool in development projects

Product optimization – Design for AM

📄 Hybrid design of additive components

Combining different AM technologies for product and process optimization

📄 AddiCut

Additive manufacturing of an optimized milling tool

📄 AM Gears – Additive manufacturing of metalpolymer gears for automotive transmissions

Development of metal-polymer composite gears manufactured by additive manufacturing

AM Process development

📄 AGENT_QualiPro

Quality management for safe and robust additive production

📄 Monitoring distortion and cracks during additive processes

Equipment development with in-situ residual stress measurement

📄 Additive Manufacturing 4.0

Mobile App for Quality Assurance

📄 Quality management in the additive production

Development of quality routines along the additive process chain

📄 Numerical simulation of additive processes

Optimizing heat flows and reducing dimensional deviations

📄 Influence of Machine Control and Dynamics on the Definition of Deposition Strategies and Travel Speeds for Laser Metal Deposition (LMD) Processes

Determination of a set of guidelines for trajectory generation in additive manufacturing (AM) processestowards the predictability of bead morphology

Pre- and post-processing for AM products

📄 Lightweight Components for Large Jets

From AM process design to finished prototypes

📄 ProFex

Process chain for the manufacturing of highly complex turbine components

📄 FERA Feasibility Study – Tools and Gears Repaired Additively

This feasibility study aimed to explore the challenges of additive manufacturing application for gear teeth repair and the evolution to a robust design

📄 Post-processing of TI6AL4V Preforms Manufactured by Wire Arc AdditiveManufacturing (WAAM)

Evaluation of the relevant aspects for the integration between additive and subtractive manufacturing process of Ti6Al4V walls produced by Wire Arc Additive Manufacturing

AM surface integrity characterization

📄 Automatic optical inspection of glass tubes

Optical inspection for continuous quality assurance

📄 FERA Feasibility Study – Tools and Gears Repaired Additively

This feasibility study aimed to explore the challenges of additive manufacturing application for gear teeth repair and the evolution to a robust design

How to cooperate with us

A step-by-step guide

- Company approaches the Fraunhofer IPK Project Office for Advanced Manufacturing at ITA with an inquiry

- Definition of project scheme

- The international team of experts, together with the company, discuss and defines and the project scope, demands and requirements

- Our team proposes the best contract model for hiring the Fraunhofer IPK Project Office at ITA, which depends on the division of work and financing source

- A proposal is developed by our team

- The contract between the parties is prepared and the company places the order (non-disclosure agreements can also be prepared in parallel)

- We carry out the project

- Presentation of results upon project completion