High Performance Manufacturing

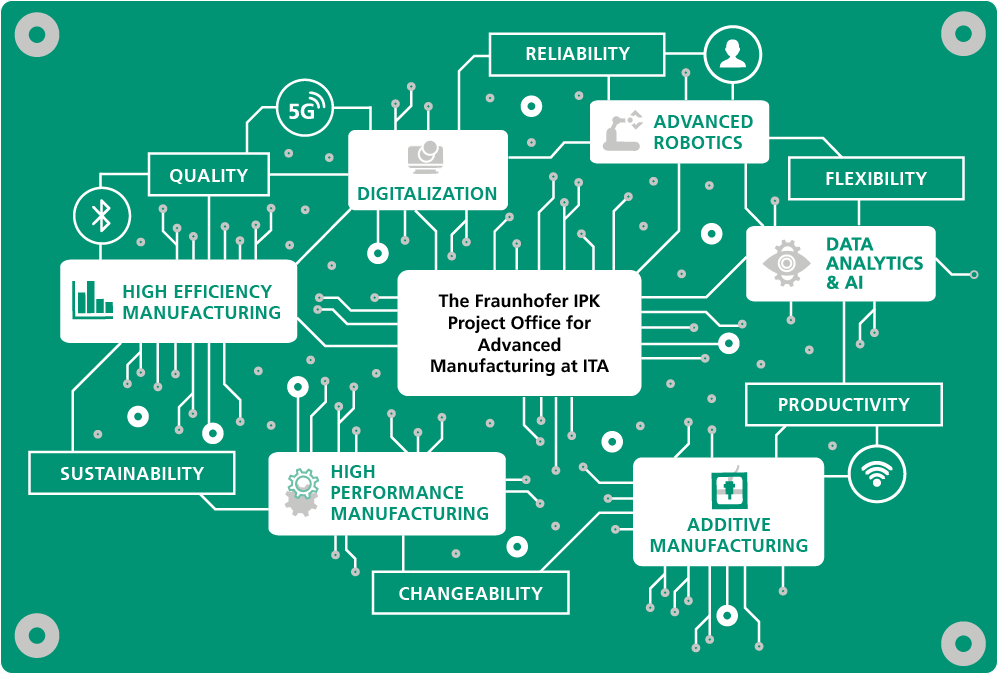

We work on the development, provision and adaptation of production and manufacturing technologies as well as the necessary machine and control technology necessary for manufacturing of innovative products. It is the Fraunhofer IPK Project Office for Advanced Manufacturing at ITA’s goal to strengthen and improve the competitiveness of our partners in the long term with application-specific detail and system solutions. Our researchers develop new machines and machining strategies, optimize existing production facilities and implement future-oriented tool concepts. We support manufacturers in the development and introduction of new product-related services.

Leer

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Development of machines, tools & devices for manufacturing processes

📄 High performance machines

New machine-tool concepts and solutions for plant and process automation

📄 Industry 4.0

Flexible Transparent Manufacturing

📄 Flexmatik 4.1

Development of more accurate process kinematics

📄 Performance Assessment of Machine Tools Based on Structural Stiffness

Mapping the machine’ structural behavior and its influence on the geometrical accuracy of a machined part

📄 EFIP-EFORB – Devices for Aircraft Structures Assembly

Development of end-effectors to complement the necessary tasks for the automation of aircraft structural assembly

📄 EXOBOT – Mobile Robotic Force Amplification System

Development of a force amplification system to handle large pipes

Development and optimization of machining processes

📄 High Performance Production

Development, deployment and adaptation of production and manufacturing technologies

📄 Industrial robots as machine-tools

Flexibility, precision and automation with industrial robots

📄 Industry 4.0

Flexible Transparent Manufacturing

📄 VISION

Performance and efficiency of industrial robot

📄 Evaluation of the cast iron Drilling process

Evaluation of the drilling process, regarding machinability of the cast iron, using minimum quantities of lubricant (MQL) and flood rating

📄 Analysis of the valve seat machining process

Evaluation of the influence of material and cutting parameters in the machinability of guide seats

📄 Optimization of the screw connection for closing a planetary gear unit

Analyze the interaction between surfaces and their connection to the state of finishing in order to optimize the screw connection used to close a planetary gear unit

📄 Machinability Evaluation of Three Similar Medium-Carbon Alloys

Evaluation of the differences between both alloys in what concern the machinability, specially the chips characteristics

📄 Machinability of the new materials for automotive valve guides

Investigation of the machinability of new materials for automotive valve guides with different surface treatment conditions

📄 Comparative study of Aeronautical Component Manufacturing using 3 and 5 axis machines

Analysis of the differences between 3-axis and 5-axis milling in aeronautical components

📄 Machinability evaluation – Drilling Process

Analysis of three Compacted Graphite Iron (CGI) types on machining operation to manufacture precision holes

Development and optimization of forming processes

📄 Tool and mould making

Development of special technological solutions & production equipment and set-up of process chains

📄 Industrie 4.0 LINK

Flexible Transparent Manufacturing

📄 Proposal for the optimization of mold and matrix machining processes

Programming procedures and definition of processes parameters.

📄 Integrity of Advanced High-Strength

Research to investigate the influence of the welding parameters on the integrity of AHSS weld spots and to understand how significant is the effect of a processing chain on the integrity when compared to the “as-welded” condition

📄 TDO 4.0 – New Die Tryout Concept

Development of online monitoring tools to diminish manual interventions during the tryout stage of sheet metal forming dies

📄 Surface defects assessment

Analysis of the feasibility to develop a defect identification system in sheet metal stamped

📄 Research and development of new materials and manufacturing processes for stamping tools that minimize surface defects

Evaluation of the results using an exerto of polymeric material in tool and die stamping

Development and optimization of welding and coating processes

📄 Laser beam and hybrid welding

Process development, parameters determination and technical & economic assessment

📄 Optimization of the welding sequence on complex assemblies

Flexible Transparent Manufacturing

📄 Industrie 4.0 LINK

Flexible Transparent Manufacturing

📄 AGE Project – Automation of the Construction and Installation of Large Scale Industrial Reservoirs

Development of a high innovative process through automatic align with industrial robots using a programming called cooperative movement

📄 Spot Welding Process

Development of AI models with data responses from resistance welding process

Development and optimization of hybrid manufacturing processes

📄 Post-processing of TI6AL4V Preforms Manufactured by Wire Arc Additive Manufacturing (WAAM)

Evaluation of the relevant aspectsfor the integration between additive and subtractive manufacturing process of Ti6Al4V walls produced by Wire Arc Additive Manufacturing

📄 New process combination for efficient metallic coatings

Combination of laser and plasma powder deposition welding in one process zone

Development of process chains for repairing of high added-value components

📄 FERA Feasibility Study – Tools and Gears Repaired Additively

This feasibility study aimed to explore the challenges of additive manufacturing application for gear teeth repair and the evolution to a robust design

📄 System technology for laser beam repair welding

Continuous quality control during laser cladding

Surface-engineered solutions for the manufacture of gears

📄 Application of the Hall Effect for the Assessment of Thermal Damage

Investigation of the proposal for a method of surface magnetic scanning through the Hall effect, without the use of component magnetization sign

📄 Development of the Powder Metallurgy chain for High Performance Automotive Gears

Application of the “integrated product development” method to the design of the powertrain components manufacturing chain

Assessment of durability and NVH in rotary systems

📄 Investigation of the effect of microalloy elements in special steels on the durability of gears

Analyze the interaction between surfaces and their connection to the state of finishing in order to optimize the screw connection used to close a planetary gear unit

📄 Assessment of the Manufacturing Chain on the Fatigue Behavior of PM Gears

Identification of the fatigue behavior of gears subjected to an alternative powder metallurgy manufacturing chain, recording them by using an S-n curve

How to cooperate with us

A step-by-step guide

- Company approaches the Fraunhofer IPK Project Office for Advanced Manufacturing at ITA with an inquiry

- Definition of project scheme

- The international team of experts, together with the company, discuss and defines and the project scope, demands and requirements

- Our team proposes the best contract model for hiring the Fraunhofer IPK Project Office at ITA, which depends on the division of work and financing source

- A proposal is developed by our team

- The contract between the parties is prepared and the company places the order (non-disclosure agreements can also be prepared in parallel)

- We carry out the project

- Presentation of results upon project completion