Data Analytics & AI

In our world view, human beings are at the heart and center of production. This is the premise under which we use and research artificial intelligence in production. We assume that companies should not only invest in hardware and software, but also systematically use their production engineers’ so-called domain knowledge. We support our partners in all their AI concerns along the entire process chain – from planning the networked factory and managing it, all the way to the smart product. We always focus on methods of analysis which give industry experts transparent results based on an intelligent combination of human know-how and machine analytics. Visual analytics allows us to explore unknown data and to examine statistical models for plausibility. Our specialized tools support data scientists in their daily work and allow industry experts to apply their knowledge in assessing and interpreting the patterns they find.

Leer

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Increase of productivity via Data analytics/Machine learning

📄 Cockpit 4.0

Semantic product data for engineering

📄 EIBA

Automated identification of used products

📄 ReLkat

Reinforcement learning for complex automation technology applications

📄 Spot Welding Process

Development of AI models with data responses from resistance welding process

Optimization of production planning and manufacturing processes via AI.

📄 EIBA

Automated identification of used products

📄 Industrie 4.0

Flexible Transparent Manufacturing

📄 Additive Manufacturing 4.0

Mobile App for Quality Assurance

Reduction of production costs through Condition monitoring & predictive maintenance

📄 Lifecycle Monitoring with the Digital Twin LINK

IoT-based services for industrial production

📄 MobiKAM

Measuring and testing with mobile cameras

📄 AMELI 4.0

Condition Monitoring in Industrie 4.0

📄 ReLkat

Reinforcement learning for complex automation technology applications

Development of data-driven business models (smart services)

📄 Smart Service Customization

Utilization of life cycle data through data-driven business models

📄 Data-driven business model

A methodology to develop smart services

Machine vision for optimization of production & logistics

📄 Components identification via app

AI-supported image processing on the smartphone

📄 Logic.Cube

Components identification via app

📄 Automatic optical inspection of glass tubes

Optical inspection for continuous quality assurance

📄 EIBA

Automated identification of used products

How to cooperate with us

A step-by-step guide

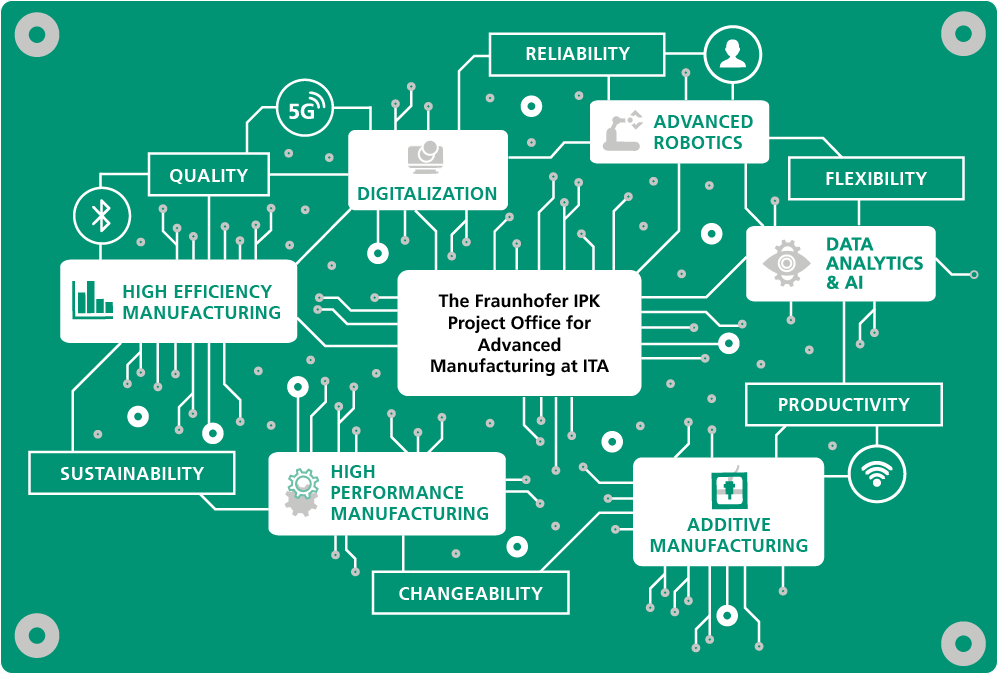

- Company approaches the Fraunhofer IPK Project Office for Advanced Manufacturing at ITA with an inquiry

- Definition of project scheme

- The international team of experts, together with the company, discuss and defines and the project scope, demands and requirements

- Our team proposes the best contract model for hiring the Fraunhofer IPK Project Office at ITA, which depends on the division of work and financing source

- A proposal is developed by our team

- The contract between the parties is prepared and the company places the order (non-disclosure agreements can also be prepared in parallel)

- We carry out the project

- Presentation of results upon project completion