High Efficiency Manufacturing

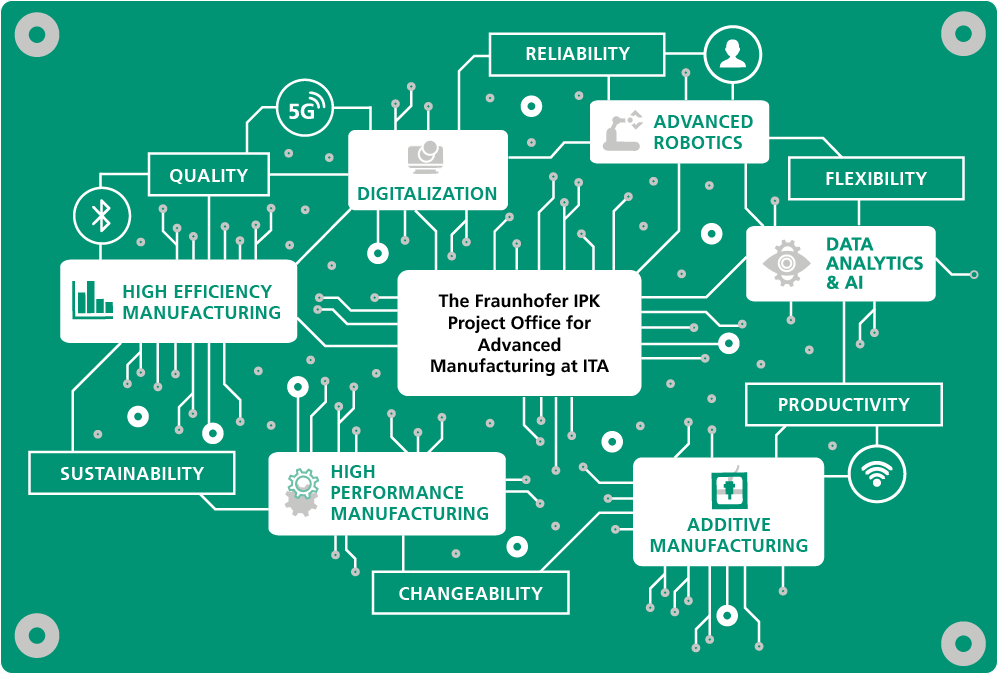

The Fraunhofer IPK Project Office for Advanced Manufacturing at ITA develops solutions for the design and management of manufacturing companies – such as organizational and business models, business processes and process organization. In this context we deal with corporate strategies and their planning, knowledge management and benchmarking, process control and information transfer. For many companies enquiries with stricter requirements for technology and quantity are now part of everyday life. How long does it take your production department to adapt efficiently and reliably to such a situation? We develop solutions to flexibly coordinate model-based production technologies and factory management systems.

Leer

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Energy efficiency strategy for manufacturing processes and production chain

📄 EnEffReg

Holistic efficiency control for production systems

📄 ENERPRO

Energy efficiency measures for production systems

📄 Energy performance analysis of spot welding process

Analysis of energy consumption and quality aspects of spot welding process by statistical approach

📄 Residual stresses heterogeneity assessment of high performance powder metallurgy gears

Comprehension of the residual stress state of gears manufactured by powder metallurgy

📄 Investigation of the effect of microalloy elements in special steels on the durability of gears

Analyze the interaction between surfaces and their connection to the state of finishing in order to optimize the screw connection used to close a planetary gear unit

Increase of production efficiency via DA/ML

📄 Cockpit 4.0

Semantic product data for engineering

📄 Additive Manufacturing 4.0

Mobile App for Quality Assurance

📄 Spot Welding Process

Development of AI models with data responses from resistancewelding process

📄 TDO 4.0 – New Die Tryout Concept

Development of online monitoring tools to diminish manual interventions during the tryout stage of sheet metal forming dies

Efficient engineering conception through Integrated Product Development (IPD)

📄 PDM/PLM Competence Center

Efficient introduction of PDM/PLM for product data integration and transparent processes

📄 Development of analysis tools for mechanical vehicle systems

Development of tools for analysis of vehicular mechanical systems for gears and crankshafts

📄 Ball Rod – Development of a Rolling Contact Fatigue Test Bench

Planning the revitalization and optimization of a bench for performing rolling contact fatigue tests with the “ball-rod” concept

📄 Development of a horizontal shaft rotor and verticalized power transmission system focused on downtime and maintenance cost reduction – Phase 1

Assessment of the technical feasibility of developing a horizontal shaft rotor wind turbine and verticalized power transmission

📄 New Washer Concept Manufacturing Process

Development of a friction test bench for tests on alternative friction surface finishes

📄 Improved Measurements of Gears Efficiency in back-to-back test rig

This research aims in a more reliable power losses measurements in a powercirculating test rig

Development of high added value manufacturing processes

📄 High Performance Production

Development, deployment and adaptation of production and manufacturing technologies

📄 Residual stresses heterogeneity assessment of high performance powder metallurgy gears

Comprehension of the residual stress state of gears manufactured by powder metallurgy

📄 Optimization of the screw connection for closing a planetary gear unit

Analyze the interaction between surfaces and their connection to the state of finishing in order to optimize the screw connection used to close a planetary gear unit

📄 Investigation of the effect of microalloy elements in special steels on the durability of gears

Analyze the interaction between surfaces and their connection to the state of finishing in order to optimize the screw connection used to close a planetary gear unit

📄 FERA Feasibility Study – Tools and Gears Repaired Additively

This feasibility study aimed to explore the challenges of additive manufacturing application for gear teeth repair and the evolution to a robust design

📄 Cutting Fluid Analysis to Aerospace Industry

Evaluation of the cutting fluids that could be used by the company and its suppliers in Aerospace Industry

📄 Proposal for the optimization of mold and matrix machining processes

Programming procedures and definition of processes parameters

Assessment of power losses in rotary systems

📄 Development of analysis tools for mechanical vehicle systems

Development of tools for analysis of vehicular mechanical systems for gears and crankshafts

📄 Improved Measurements of Gear Efficiency in Back-to-Back Test Rig

This research aims in a more reliable power losses measurements in a powercirculating test rig

How to cooperate with us

A step-by-step guide

- Company approaches the Fraunhofer IPK Project Office for Advanced Manufacturing at ITA with an inquiry

- Definition of project scheme

- The international team of experts, together with the company, discuss and defines and the project scope, demands and requirements

- Our team proposes the best contract model for hiring the Fraunhofer IPK Project Office at ITA, which depends on the division of work and financing source

- A proposal is developed by our team

- The contract between the parties is prepared and the company places the order (non-disclosure agreements can also be prepared in parallel)

- We carry out the project

- Presentation of results upon project completion